Foam TPU three advantages become killer applications Shoes

2016-07-06 03:26:01

In this society, the real social progress must be technological innovation and the technological revolution, any field is no exception.

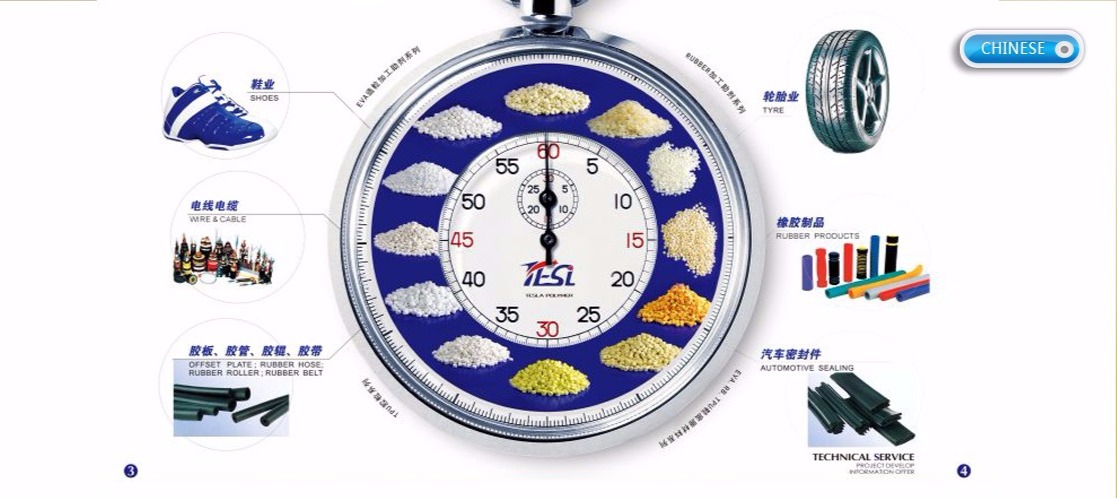

There is a material led to the footwear industry revolution in the past 20 years, it is the EVA. EVA foam can be made through the soles become sufficiently light, and have a certain elasticity so that the sole of EVA resin having appropriate cushioning, which led to the current most gentle casual shoes running shoes are invariably adopted EVA as the sole material.

China in the amount of up to 45 million tons per year in the shoe occupy the entire EVA market accounted for more than 53%

Due to technical limitations in the past 10 years, China EVA resin market import dependence has not low, Chinese manufacturing enterprises in the single digits the number of long-term maintenance, Sinopec Yanshan, Sinopec Yangzi BASF plus Formosa Plastics Group, a virtual monopoly on the market, Of course, these prices make the company has been very enjoyable.

Now comes the killer, it is the TPU, its full name is a thermoplastic polyurethane elastomer, is well known, the biggest advantage of polyurethane elastomer has three points:

1, formulations great plasticity, that is, by adjusting the formula can be produced from the softest to the hardest of products;

2, in particular, wear-resistant, it is three times the wear resistance of natural rubber, natural rubber is to know all the varieties most durable rubber;

3, it can be made very transparent and any color of the products.

Before polyurethane elastomer does not appear, it requires considerable wear our traditional soles are made of natural rubber, carbon black reinforcing fillers, that is, we see the soles are usually black; if you want to buy or light color shoe soles, wear resistance will be greatly reduced, and can not be transparent. When the polyurethane elastomer is used as the sole when it has been more resistant than black rubber soles, and may be transparent or colored; but if the big bottom and full midsole with a polyurethane elastomer, these shoes very heavy, wear uncomfortable; and inability to be made before the porous foam, no one would choose to do in the end polyurethane elastomer; it is common practice to do with EVA foam midsole, and then paste the bottom layer thin TPU bigger bottom, so wear shoes both light and wearable.

TPU production of several major raw material used in recent years, prices showed a gradual downward trend, some materials such as BDO has dropped significantly, so that the TPU with growing competitiveness.

We are convinced that in the next five years EVA used in applications in the field may exceed Qicheng shoe will be replaced by the new TPU, of course, this technique can also be successfully pipe on EVA industry this is not a good news.